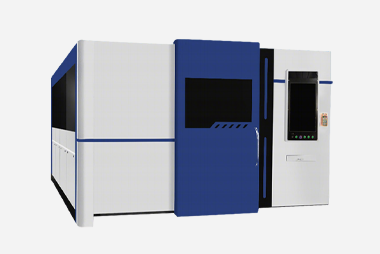

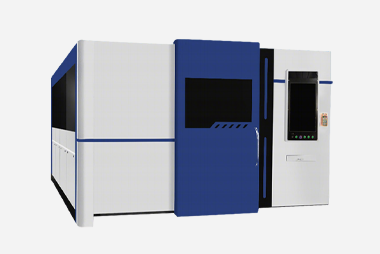

Full-Enclosure Exchange-Table Fiber Laser Cutting Machine

Unlock faster production, cleaner workshops, and safer operations—all in one machine.

With a fully enclosed body and dual exchange tables, this system boosts capacity and keeps your team protected while running non-stop.

Why Choose the Fiber Laser Cutter?

Designed for manufacturers who demand speed, safety and consistent production output, this full-enclosure dual-table laser cutter delivers the efficiency and reliability required for modern high-volume metal fabrication.

Dual Exchange Tables

Experience up to 80% higher throughput with simultaneous cutting and loading/unloading, enabling continuous production.

Full Enclosure Safety

Laser-proof glass and sealed structure prevent smoke, dust and sparks, ensuring CE-level operator protection and a clean workshop environment.

24/7 Industrial Design

Robust frame, stable transmission system and intelligent control guarantee long-term reliability for high-volume manufacturing.

For Large-Scale Fabrication

Built to support large-format sheet metal production in demanding industrial environments.

Extreme Dynamic Performance

High-speed motion control and optimized drive systems achieve rapid acceleration, smooth corner transitions and stable high-speed cutting for both thin and thick plates.

Bus-Type Intelligent CNC

Industrial bus communication ensures ultra-low latency, precise multi-axis synchronization and improved cutting accuracy in continuous operation.

Intelligent Vibration Suppression

Automatically detects and compensates for mechanical oscillation, enabling cleaner micro-holes, sharper corners and better performance during high-speed processing.

Adaptive Air Pressure Calibration

Automatically adjusts nitrogen, oxygen and air pressure based on material and cutting path, reducing piercing time, minimizing burrs and lowering gas consumption.

Matrix Extraction System

Segmented negative-pressure dust removal ensures clean air flow throughout the entire enclosure, protecting optics and meeting industrial environmental requirements.

Professional-GradeSafety Protection

Fully enclosed structure, anti-spark shielding, heat-resistant panels and Class-1 laser protection glass ensure safe, reliable cutting in heavy-duty industrial environments.

Technical Parameters

Batch production of sheet metal components for OEM customers.

| Parameter | Value |

|---|---|

| Models | H-3015/H-4015/H-4020/H-6020/H-6025/H-8025/H-13025/H-13030 |

| Laser Power | 3000W–20000W |

| Laser Source | IPG / Raycus / MAX |

| Working Area | 1500×3000 / 2000×4000 / 2000×6000 mm |

| Cutting Accuracy | ±0.03 mm |

| Repeatability | ±0.02 mm |

| Max Acceleration | 1.5–2.0 G |

| Max Linkage Speed | Up to 120 m/min |

| Transmission System | Dual servo motors + bus-level CNC |

| Cooling | Industrial dual-circuit chiller |

| Supported Materials | Carbon steel, stainless steel, aluminum, brass, galvanized plate |

Industry Applications & Samples

· Automotive Manufacturing · Industrial Equipment & Machinery · Stainless Steel Products · Metal Fabrication Workshops

Ready to Upgrade Your Production?

Leave your cutting requirements, and our engineers will provide a tailored solution and price quote within 24 hours.

FAQ

Here are the most common technical and purchasing questions from real manufacturers.

What advantages does a full-enclosure design provide?

The full protective enclosure blocks laser radiation, contains sparks, reduces smoke and ensures safer working conditions, meeting CE Class-1 laser safety standards.

What is the benefit of a dual exchange table system?

The exchange platforms allow simultaneous cutting and loading/unloading, increasing production efficiency by up to 80% and reducing idle time.

What thickness of metal can this machine cut?

With power up to 20 kW, it can cut:

• Carbon steel: 40 mm+

• Stainless steel: 30 mm

• Aluminum: 20 mm

• Brass/Copper: Depending on power & configuration

Specific values depend on your laser power selection.

Is the machine suitable for continuous 24/7 operation?

Yes. The rigid frame, advanced servo system and high-stability CNC control are engineered for long-term industrial production environments.

How does the matrix extraction system improve cutting performance?

It removes smoke, dust and metal particles efficiently, protecting optical components, ensuring stable cutting quality and keeping the enclosure clean.

Does the machine support high-power laser sources?

Absolutely. It supports 3 kW to 20 kW fiber lasers for high-speed thin plate cutting and efficient thick plate processing.

What industries benefit most from this machine?

Automotive, machinery manufacturing, industrial equipment, stainless steel products, construction hardware and OEM metal fabrication.

What maintenance is required for long-term stability?

Routine maintenance includes lens cleaning, lubrication, filter replacement, gas pressure calibration and periodic system checks to maintain optimal performance.

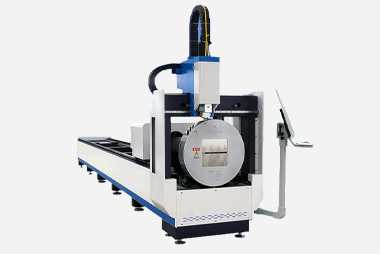

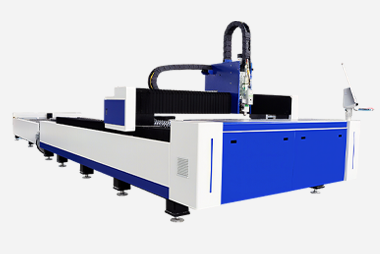

Related Products

This is the heading

This is the heading

This is the heading