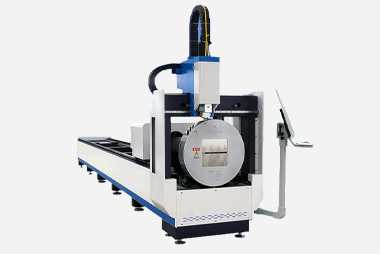

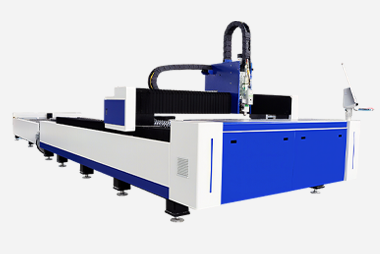

Single-Platform Fiber Laser Cutting Machine

A compact, cost-effective sheet metal laser cutter designed for small and medium workshops. Ideal for stainless steel, carbon steel and aluminum cutting with high stability and lower investment.

Why Choose Single-Platform Fiber Laser Cutting Machine?

• Faster setup • Lower operating cost

Compact Single-Table Design

Optimized for small workshops with limited space while maintaining stable sheet metal cutting performance.

High Cutting Quality

Delivers smooth edges, narrow kerf and minimal heat distortion—reducing secondary processing time.

Lower Investment, Higher Value

An ideal entry-level laser machine for metal fabrication businesses upgrading from plasma or mechanical cutting.

Easy to Operate & Maintain

User-friendly CNC interface and simplified structure reduce training time and daily maintenance.

Bus-Type Intelligent CNC Control

High-speed industrial bus communication ensures ultra-low latency, precise synchronization and stable high-speed motion control during long-duration cutting.

Intelligent Vibration Suppression

Real-time motion compensation reduces oscillation during rapid acceleration, creating sharper corners, cleaner micro-holes and more accurate contours.

Adaptive Air Pressure Calibration

Automatically adjusts gas pressure based on materials and cutting paths. Improves piercing quality, reduces burrs and lowers nitrogen/oxygen consumption.

Matrix Extraction System

High-efficiency dust and fume extraction improves cutting stability, protects optical components and maintains a clean working environment.

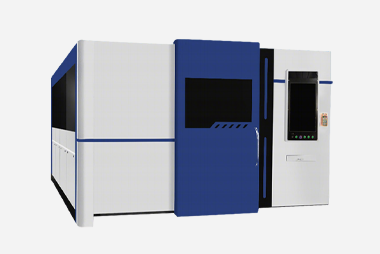

Professional-Grade Safety Protection

Industrial anti-spark shielding and heat-resistant safety structure ensure reliable long-term operation in demanding manufacturing environments.

Technical Parameters

Specifications may vary by laser power and configuration. Contact us for the full datasheet.

| Parameter | Value |

|---|---|

| Models | A-3015/A-4015/A-4020/A-6020/A-6025/A-8025/A-13025/A-13030 |

| Laser Power | 1000W–6000W |

| Laser Source | IPG / Raycus / MAX |

| Working Area | 1300×900 / 1300×2500 / 1500×3000 / 2000×4000 |

| Cutting Accuracy | ±0.03 mm |

| Max Cutting Speed | Up to 40 m/min (depending on material) |

| Supported Materials | Carbon steel, stainless steel, galvanized sheet, aluminum, brass |

| Cooling System | Industrial chiller |

| Control Method | Bus-type CNC + DSP motion |

| File Format | DXF / DWG / AI / PLT / Step |

| Max.Acceleration | 1.2G |

Industry Applications & Samples

· Automotive Parts · Home Appliances · Sheet Metal Fabrication · Machinery Manufacturing

Tell us about your cutting requirements.

Our engineers will customize a solution and provide a quotation within 24 hours.

FAQ

Here are the most common technical and purchasing questions from real manufacturers.

What type of users is the Single-Platform Fiber Laser Cutting Machine designed for?

This model is optimized for small and medium metal fabrication workshops, job shops and manufacturers with limited space who need stable sheet metal cutting performance at a lower investment cost.

What materials can the single-platform fiber laser cutter process?

It supports a wide range of sheet metals including carbon steel, stainless steel, galvanized steel, aluminum, brass and alloy materials.

How thick of a metal sheet can it cut?

Cutting thickness depends on the selected laser power:

Carbon steel: up to 14 mm

Stainless steel: up to 8 mm

Aluminum: up to 6 mm

Higher-power configurations are available for thicker materials.

What is the cutting accuracy of the machine?

With a bus-type CNC system and vibration suppression technology, the single-platform fiber laser cutting machine reaches cutting accuracy up to ±0.03 mm, ensuring stable quality for precision sheet metal parts.

Does the machine support automatic gas pressure adjustment?

Yes. The adaptive air pressure calibration system automatically adjusts nitrogen, oxygen or air pressure for smoother cutting, faster piercing and reduced gas consumption.

What software does the machine use for programming and nesting?

It includes a professional CAD/CAM nesting system that supports DXF, DWG, AI, PLT and STEP formats. Automatic nesting and path optimization help reduce material waste and improve efficiency.

What are the advantages of a single-platform machine compared to a dual-exchange platform?

Single-platform machines have a smaller footprint, lower investment, simpler maintenance and faster setup, making them ideal for small workshops or businesses with mixed-order, low-to-medium production volumes.

What after-sales support and warranty does UniLaser provide?

We offer 24/7 online engineer support, remote troubleshooting, training guidance and a 3-year machine warranty, ensuring long-term stable operation and quick response for all technical issues.