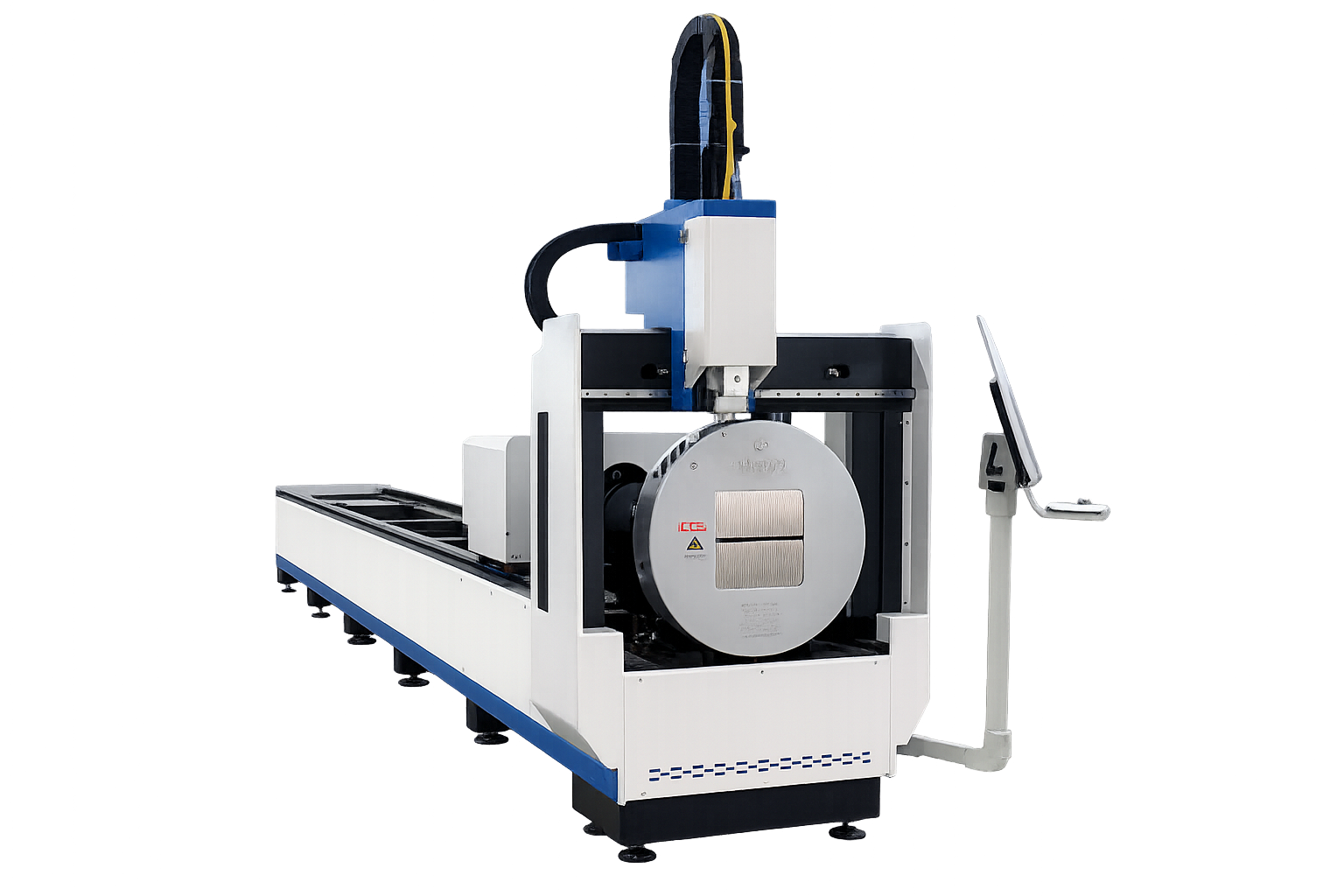

Laser Tube Cutting Machine

High-precision fiber laser cutting solution for metal tubes including stainless steel, carbon steel, aluminum, copper, and alloy materials. Ideal for manufacturers who need accuracy, speed and consistent cutting quality.

Why Choose T-Series?

Designed for heavy-duty industrial applications, offering 30% higher efficiency than standard models.

High Precision

Fiber laser + CNC control delivers stable cutting accuracy down to ±0.03 mm for complex tube profiles.

Automated Productivity

Auto loading, rotation and multi-chuck options—including 0-tail cutting—boost efficiency while cutting labor costs.

Eco-Friendly Cutting

Low energy use and reduced waste help manufacturers meet environmental requirements.

CE & ISO Certified

Complies with CE and ISO industrial safety standards for reliable, factory-grade operation.

Bus-Level High-Speed CNC Control

High-speed industrial bus system ensures ultra-low latency, synchronized motion and stable high-speed tube cutting.

Adaptive Air Pressure Control

Automatically adjusts cutting gas pressure for smoother edges, faster piercing and reduced overall gas consumption.

Intelligent Vibration Suppression

Dynamic compensation keeps the cutting head stable at high speed, enabling sharper corners and cleaner micro-holes.

Industrial Fire-Resistant Safety Design

Fully shielded cutting area with anti-spark protection ensures long-term stable operation in heavy-duty production environments.

Technical Parameters

Comparison of T2 (Standard) and T3 (High-Power) models

| Parameter | Value |

|---|---|

| Models | T-3015 / T-4015 / T-4020 / T-6020 / T-6025 / T-8025 / T-13025 / T-13030 |

| Max. Speed | 120 m/min |

| Positioning Accuracy | ±0.3 mm/m |

| Repeatability | ±0.02 mm/m |

| Max. Acceleration | 1.2G |

| Cooling Method | Water cooling |

| Z-Axis Travel | 150 mm |

| Laser Wavelength | 1070 ±5 nm |

| Control Method | DSP |

| Operating Temperature | -10°C ~ +40°C |

| Compatible Software | CorelDraw / AutoCAD / Photoshop / AI / Others |

Industry Applications & Samples

Our tube laser cutting machine is widely used in: Automotive & Vehicle Part Manufacturing. Furniture & Interior Decoration. Construction & Industrial Structures

Ready to Upgrade Your Production?

Tell us your cutting requirements, and our engineers will provide a tailored solution and quotation within 24 hours.

FAQ

Here are the most common technical and purchasing questions from real manufacturers.

What materials can the laser tube cutting machine process?

Our fiber tube laser cutter supports stainless steel, carbon steel, aluminum, copper, alloy steel and other common metal tubes. Different laser powers allow flexible cutting performance for various materials.Typical round/square/rectangular tube thickness capability:

Carbon steel: 0.8–10 mm

Stainless steel: 0.8–8 mm

Aluminum alloy: 0.8–6 mm

Mild alloys: 0.8–6 mm

Exact cutting capability depends on the laser source (1 kW–6 kW). We will recommend the optimal configuration based on your tube size, wall thickness, and production volume.

How does the bus-type CNC control system improve cutting accuracy and stability?

The system uses high-speed industrial EtherCAT bus communication, offering:

Low latency response for dynamic cutting

High-precision path synchronization, especially for dual-chuck movement

Real-time compensation for acceleration, vibration, and path deviation

Stable continuous processing during high-speed cuts

This significantly enhances consistency on tight-tolerance jobs such as fitness frames, automotive tubes, and HVAC brackets.

What are the key advantages of the adaptive air-pressure calibration system?

The machine automatically adjusts gas pressure based on:

Material type

Wall thickness

Cutting speed

Benefits include:

Smoother kerf and clean edges

Reduced dross during high-speed cutting

Lower gas consumption (saves 10–25% depending on material)

Better stability on thin-wall tubes

This ensures consistent results without requiring manual pressure tuning.

How does the vibration-suppression algorithm affect cut quality on thin-wall tubes?

The control system analyzes motion in real time and applies adaptive counter-vibration compensation, providing:

Stable movement at high acceleration

No chatter marks on thin wall tubes

Improved precision on:

Micro holes

Sharp corners

Multi-angle intersections

High-density hole groups

This is especially valuable for fitness frames, automotive structures, and lightweight tubing.

What types of CAD/CAM files does the built-in software support?

Our integrated tube CAD/CAM system supports:

STEP / IGES / DWG / DXF / STL / Tube-specific formats

Auto nesting for tubes

Common-line cutting

Batch production programming

Fly-cutting for thin-wall tubes

Automatic remnant management

The software is designed for fast programming and minimal operator training.

How much maintenance does the cutting head and chuck system require?

Routine maintenance is minimal and includes:

Inspecting lens cleanliness (daily or weekly depending on usage)

Checking the protective lens and nozzle condition

Lubricating linear guides and ballscrews

Monitoring chuck jaws and torque output

Ensuring stable gas supply and water-cooling

Under normal production load, consumables and wear components have long service life and low replacement cost.

What safety mechanisms are included to prevent fire risks and spark damage?

The machine features a professional-grade fire-resistant protection system, including:

High-temperature-resistant shielding around the cutting zone

Spark-isolation structure to prevent splash damage

Temperature monitoring sensors

Emergency stop and electronic interlock systems

Overload & torque protection on dual chucks

These ensure safe long-term operation and reduce risk exposure in 24/7 industrial environments.

Can the machine be integrated with automated loading/unloading systems?

Yes. We support:

Automatic tube loaders

Tube bundle feeders

Unloading racks / sorting systems

MES/ERP production line integration

For high-volume clients, we also provide full customized solutions including upstream cutting, bending, punching, and downstream welding/assembly integration.

Related Products

This is the heading

This is the heading

This is the heading